Special Sale Save Now

British Institute of Lasers

Useful Links

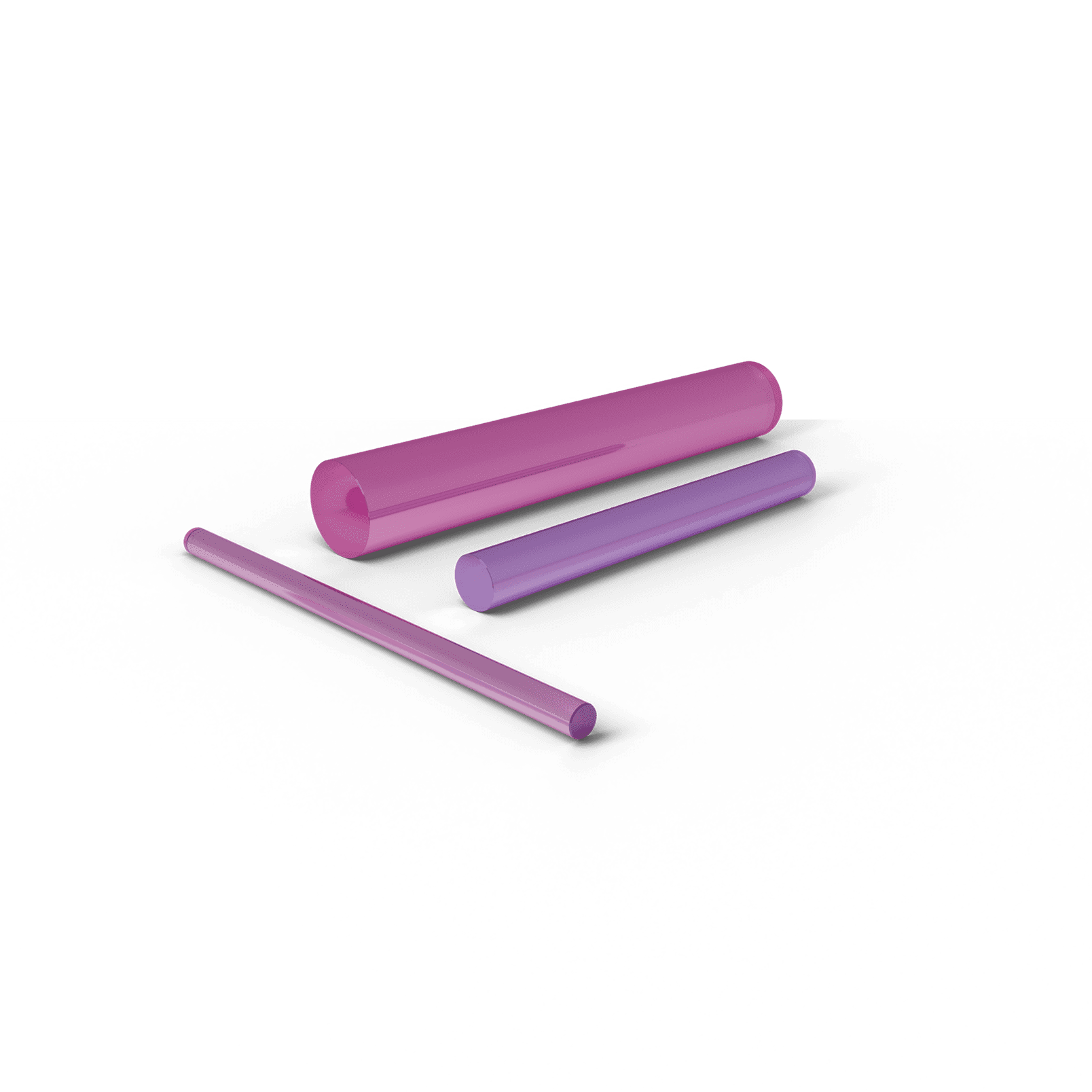

Laser Rods

(3 Customer Reviews)

Quality-tested for reliability and longevity, they’re the trusted choice for clinics and engineers alike.

Key Benefits At A Glance

Built for Demanding Workloads

Multi-System Compatibility

Exceptional Energy Delivery

Trusted Across Industries

Frequently Asked Questions

We supply a broad range of solid-state laser rods for aesthetic, medical and industrial systems. That includes rods for Alexandrite, Nd:YAG, Diode-pumped solid state and Ruby-based platforms. If you tell us your machine brand, model and wavelength, we can usually match a suitable rod from our stock or advise on a precise alternative.

In most cases, yes. Our rods are produced to fit many of the leading hair removal and aesthetic systems in regular use. The easiest way to check is to send us your machine make, model and, if possible, the current rod dimensions. We then confirm compatibility before you place an order, so you are not guessing or hoping it will fit.

Service life depends on how hard the system is driven. High repetition rates, aggressive fluences and poor cooling will shorten the life of any rod. With sensible settings and decent maintenance, our rods give stable, predictable output across a long run of treatment sessions. Many clinics fit a rod, monitor output over time, then replace on a planned schedule rather than waiting for noticeable drop off.

Ideally we need the machine brand and model, wavelength, rod diameter, rod length and dopant type or concentration, if you have it. A quick photo of the old rod with a ruler next to it is often surprisingly helpful. The more accurate your information, the easier it is for us to match the geometry and optical performance properly.

Yes. We hold a selection of diameters, lengths and dopant concentrations for popular Alexandrite and Nd:YAG platforms, as well as other specialist systems. This means we can tune the rod choice to your energy requirements rather than forcing a one size fits all approach. If you have very specific specs, we can look at a made-to-order option.

We can supply custom and OEM rods for manufacturers, distributors and larger clinic groups. That might mean bespoke sizing, particular dopant levels, tighter tolerance on polish, or private label supply. For these projects we discuss drawings, performance targets and volume, then agree a practical production plan with you.

Yes. Our in-house engineers can guide you through safe removal of the old rod and installation of the new one. Alignment procedures vary between machines, so we talk in the context of your system rather than giving vague advice. For UK-based customers, we can also discuss on-site engineering support or service visits if you prefer someone to handle the work for you.

Laser rods should be handled with care, using clean gloves and a dust free area. Avoid touching the optical surfaces directly. Keep them in their protective packaging until you are ready to install, and store them in a dry, stable environment away from vibration and strong temperature swings. Good handling keeps the polish and coating in the best possible condition.

Standard rods for common systems are usually held in stock and dispatched within 1 to 2 working days. Delivery across mainland UK is sent tracked so you can plan your fitting work with some confidence. Custom or OEM batches take longer, as they involve dedicated production, polishing and testing. We confirm lead times clearly before you sign anything off.

Yes, we also support research labs, universities and industrial users. If you have a marking, welding or materials processing system that needs a specific rod, send us the technical details. We can often either match a suitable rod or discuss a custom run if the design is more unusual.

Each rod is inspected for surface quality, polish, coating integrity and dimensional accuracy. We keep a tight eye on consistency because small variations can show up quickly in beam quality. By checking rods thoroughly before dispatch, we help clinics and engineers avoid frustrating rework once the system is opened up.

If a rod does not match the agreed specification, contact us straight away. We will ask for photos and details of the issue, then work through a practical fix, whether that means replacement or a different configuration. The aim is straightforward, functional support so your machine gets back into service without a long, drawn out saga.